Heat Exchangers

Energy saving solutions for Apartments, Houses, Commercial premises, Industrial facilities & Public buildings.Heat exchangers are essential part of any kind of HVAC system nowadays. Heat exchangers contribute substantially towards energy conservation and reduction in energy bills.

The main function of a heat recovery system is to increase the energy efficiency by reducing energy consumption and also by reducing the cost of operating by transferring heat between two gases or fluids, thus reducing the energy bills.

The heat exchangers are the best known devices for this purpose. In heat exchangers, as the name suggests, there is a transfer of energy from one fluid to another. Both these fluids are physically separated and there is no direct contact between the fluids.

There are different types of heat exchangers such as shell and tube, U tube, shell and coil, helical, plate etc. The transfer of heat can be between steam and water, water and steam, refrigerant and water, refrigerant and air, water and water. Now let’s take a look as to what are the different types of heat exchangers.

Stars Electro Mechanical can assist you with making the right choice. We appreciate the opportunity to install, service, and test & inspect your every Heat Exchanger need.

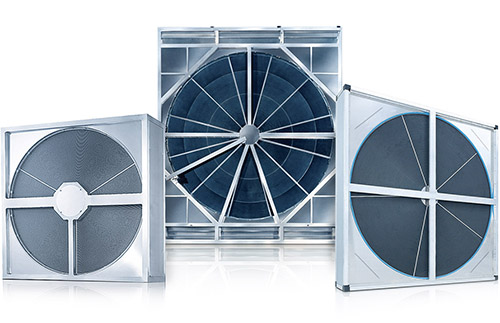

Rotary Wheel Type Heat Exchanger

A rotary wheel type heat exchanger has a large surface cylinder which is attached to the shaft. It has got a gas permeable material inside it. When the cylinder rotates, both the gases move in a counter flow pattern axially to the shaft.

The heat from the warm gas is absorbed by the gas permeable material and then it is transferred to the colder gas. Sometimes hygroscopic material is put on the gas permeable material to absorb the moisture from the gases.

Thus the moist gas becomes dry and transfers the moisture to the dry gas. Both latent and sensible heat is transferred in this system.

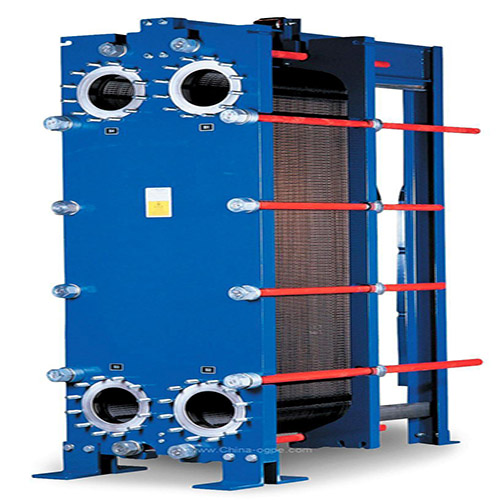

Fixed Plate Heat Exchangers

Both the gases and fluids flow separately in these alternate plates and the transfer of heat takes place between them. The flow can be counter flow, parallel flow or cross flow.

Heat Pipe Exchangers

This type of heat exchanger has an evaporator and a condenser separated by a plate. It has tubes running parallel and separated from each other. On the evaporator side the hot air transfers its energy to the liquid refrigerant and thus boiling it.

The vapor refrigerant now passes through the pipes to the condenser side. The opposite process takes place. The cold air now passes over the vapor refrigerant. The vapor refrigerant after transferring its energy turns to liquid and flows though the pipes to the evaporator side.

This type of heat exchanger generally uses parallel flow patterns. either application and can be installed in either position as supplied from the factory.

Run- Around System

In this type of system, a pump circulates water or any other liquid through the system. There are coils that are mounted in either series or parallel to facilitate maximum amount of heat transfer. This type of system is beneficial in any season.

This means that if the outside air is warmer than the exhaust air, the exhaust air pre cools outside air. And if the outside air is cooler than the exhaust air, the exhaust air pre heats the outside air, making the system more and more energy efficient.

Hot Gas Heat Exchanger

The HVAC system’s compressor generates heat by compressing refrigerant. This heat can be captured and used for heating domestic water. For this purpose a heat exchanger is placed in between the compressor and the condenser.

The water that is to be heated is circulated though this heat exchanger with the help of a pump whenever the HVAC system is on.

Double Bundle Condenser Heat Exchanger

This heat exchanger consists of two sets of water tubes in the condenser shell. The superheated gas is forced into the shell where the transfer of heat to the water takes place through the tubes.

Heat Jackets

Water jackets are kept at the sides of a reciprocating engine or a gas turbine to absorb the heat generated. This heat can be used for generating steam or for heating water or fuel oil.

Hot Drain Heat Exchangers

Heat from the hot condensate used in the kitchen, bathrooms or laundry system can be used for boiling water.Condensate is continuously formed when the release of heat takes place.

A heat exchanger placed in the condensate return can take the condensate heat for heating water.

Stars Electro Mechanical are experts in providing low maintenance and durable heat exchangers with unique designs to enable high heat transfer, save you considerable time and money, and improve your system’s energy efficiency.