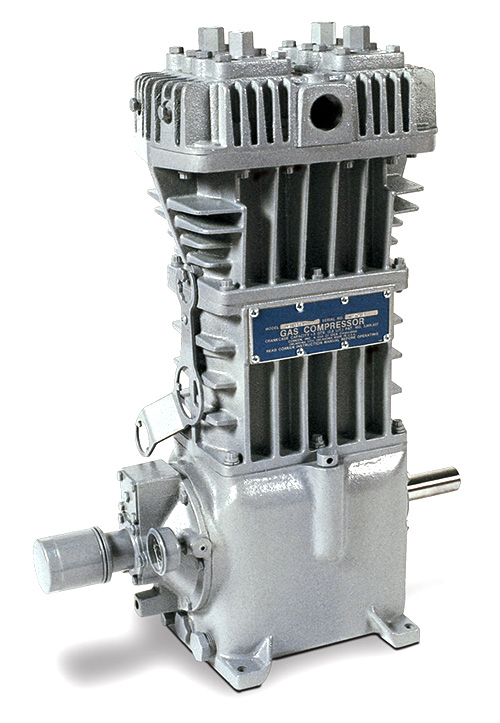

Compressors

Cost Effective, Less Noise, Minimal Maintenance Compressor solutions.

An electric motor can also be used to drive it directly. The hermetic compressor has a motor which is sealed inside a housing with the compressor, hence a crankshaft seal is not required. The motor rotor is located either at the top or bottom of the unit.

The air conditioner compressor is the heart of your cooling system. It is the most commonly misdiagnosed component in the system. At least one third of the time that the unit is said to have a “bad compressor”, the compressor is in fact not the problem.

Stars Electro Mechanical can assist you with making the right choice. We appreciate the opportunity to install, service, and test & inspect your every Compressor need.

Scroll Compressors

A scroll compressor operating in reverse is known as a scroll expander, and can be used to generate mechanical work from the expansion of a fluid, compressed air or gas. Many residential central heat pump and air conditioning systems and a few automotive air conditioning systems employ a scroll compressor instead of the more traditional rotary, reciprocating, and wobble-plate compressors.

A scroll compressor uses two interleaving scrolls to pump, compress or pressurize fluids such as liquids and gases. The vane geometry may be involute, Archimedean spiral, or hybrid curves.

Often, one of the scrolls is fixed, while the other orbits eccentrically without rotating, thereby trapping and pumping or compressing pockets of fluid between the scrolls. Another method for producing the compression motion is co-rotating the scrolls, in synchronous motion, but with offset centers of rotation. The relative motion is the same as if one were orbiting.

Another variation is with flexible (layflat) tubing where the archimedean spiral acts as a peristaltic pump, which operates on much the same principle as a toothpaste tube. They have casings filled with lubricant to prevent abrasion of the exterior of the pump tube and to aid in the dissipation of heat, and use reinforced tubes, often called ‘hoses’. This class of pump is often called a ‘hose pumper’.

Ducted Air Handlers

The intake gas enters the suction manifold, then flows into the compression cylinder where it gets compressed by a piston driven in a reciprocating motion via a crankshaft, and is then discharged. Applications include oil refineries, gas pipelines, chemical plants, natural gas processing plants and refrigeration plants. One specialty application is the blowing of plastic bottles made of polyethylene terephthalate (PET).

In the ionic liquid piston compressor many seals and bearings were removed in the design as the ionic liquid does not mix with the gas. Service life is about 10 times longer than a regular diaphragm compressor with reduced maintenance during use, energy costs are reduced by as much as 20%.

The heat exchangers that are used in a normal piston compressor are removed as the heat is removed in the cylinder itself where it is generated. Almost 100% of the energy going into the process is being used with little energy wasted as reject heat.

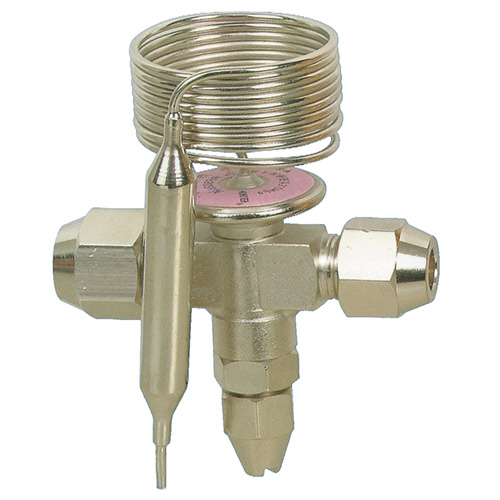

Thermostatic Expansion Valves

There are two main types of thermal expansion valves: internally or externally equalized. The difference between externally and internally equalized valves is how the evaporator pressure affects the position of the needle. In internally equalized valves, the evaporator pressure against the diaphragm is the pressure at the inlet of the evaporator, whereas in externally equalized valves, the evaporator pressure against the diaphragm is the pressure at the outlet of the evaporator. Externally equalized thermostatic expansion valves compensate for any pressure drop through the evaporator.

Internally equalized valves can be used on single circuit evaporator coils having low pressure drop. Externally equalized valves must be used on multi-circuited evaporators with refrigerant distributors. Externally equalized TXVs can be used on all applications; however, an externally equalized TXV cannot be replaced with an internally equalized TXV.

Our compressors are engineered for higher efficiency, lower sound levels, superior durability and unsurpassed reliability. They allow the integration of new and environmentally-friendly refrigerants into your systems, while seamlessly improving efficiency and performance levels.